Stacker Stereoscopic warehouse

Intelligent storage is the goods on the shelf are put and taken by the stacker, and then the conveying line is delivered to the warehouse keeper. Goods management is a special storage management system. Intelligent warehousing makes full use of warehouse space, and the storage density per unit area is much larger than that of traditional warehousing. The three-dimensional warehouse can store the goods flexibly, and the goods can be stored in any empty warehouse.

Stereoscopic warehouse mother and child

The automated three-dimensional warehouse of the shuttle bus is also called the shuttle bus system, which is composed of shuttle bus, shuttle bus, walking track, roadway shelf, pallet elevator, pallet conveying system, automatic control system, warehouse management software, etc.

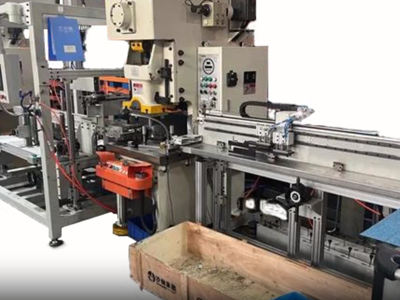

The truss manipulator is a motion system of linear motion unit combination, which is more cost-effective than the joint robot, has strong mechanical properties and greatly expands the range of motion, and is an indispensable structural form in the field of automation. Widely used in machine tool loading and unloading, handling, palletizing, automobile manufacturing, electronic appliances, medical, photovoltaic, aerospace, marine shipbuilding and many other fields.

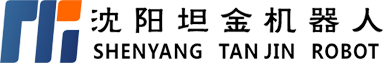

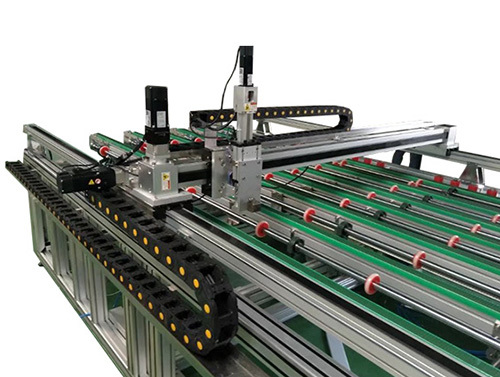

Machine tool loading and unloading

Machine tool loading and unloading: manipulator cooperates with gripper, conveying line and upper computer to realize automatic loading and unloading, and realizes product counting statistics according to instructions given by upper computer or operator.

Non-standard customized equipment is generally customized according to customer's on-site process requirements according to process requirements. Our company can make non-standard equipment with multiple degrees of freedom of movement, up to 32 servo shafts and 28 cylinder motion equipment, as well as servo wire rolling equipment that cannot be realized by machine tools.

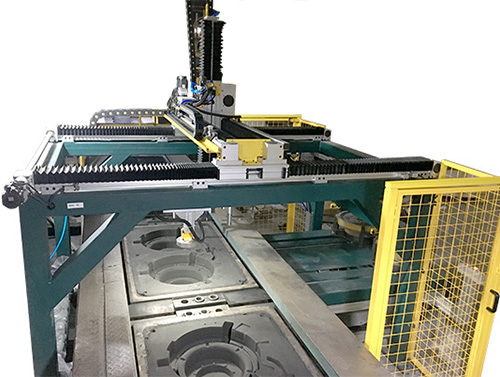

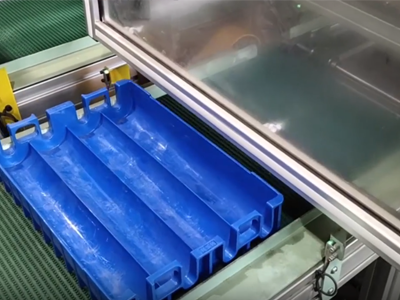

Mechanical hand supporting equipment

Manipulators in automated assembly lines are generally used with conveying lines and grippers. Our company provides supporting conveying lines, customized grippers, protective guardrails and other components.

Defect Detection in Workpiece Motion

The moving position of the workpiece must correspond to the triggering time of the camera when the moving state of the workpiece is photographed.

Complex shape workpiece defect detection

Surface detection of workpieces with complex shapes is generally conducted at multiple angles and multiple stations to take photos for multiple times before all surfaces are detected without dead angles. For example, using multiple cameras to take photos at the same time under the condition of cost can greatly reduce the number of photos or stations.