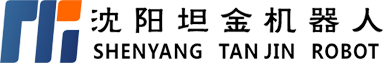

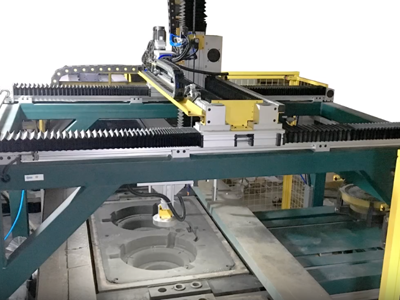

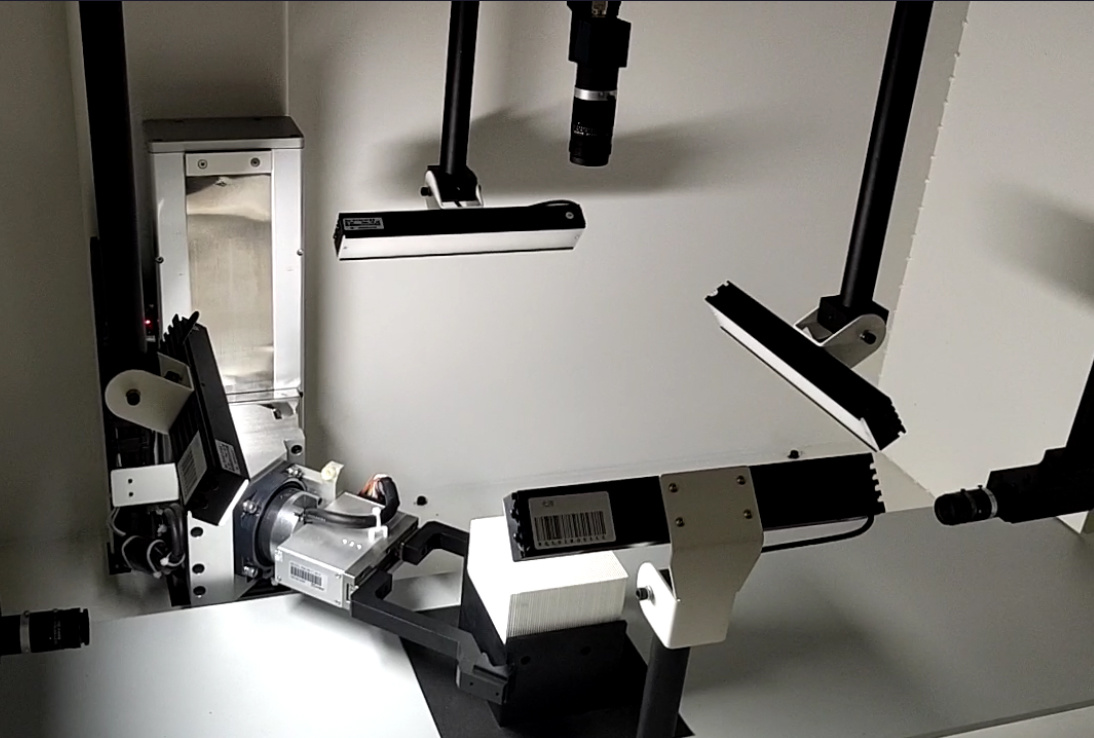

Complex shape workpiece defect detection

Surface detection of workpieces with complex shapes is generally conducted at multiple angles and multiple stations to take photos for multiple times before all surfaces are detected without dead angles. For example, using multiple cameras to take photos at the same time under the condition of cost can greatly reduce the number of photos or stations.

Key words:

Classification:

Product Description

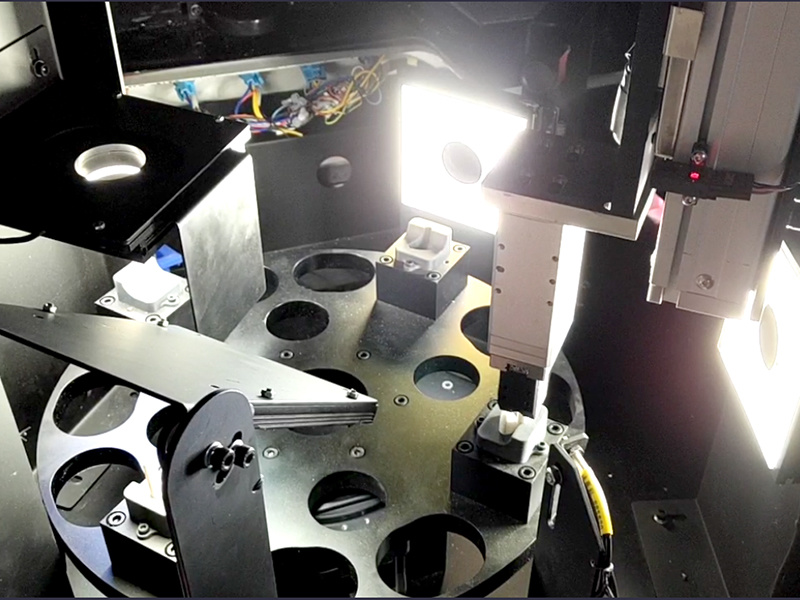

Headset shell detection

Surface detection of workpieces with complex shapes is generally performed at multiple angles and multiple stations to take photos for multiple times. For example, earphone shell detection can realize no dead angle detection through shooting at multiple cameras and multiple stations at different angles.

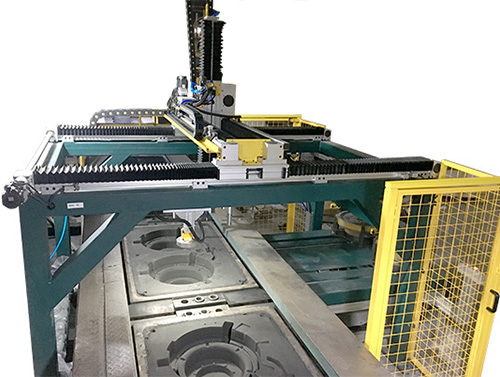

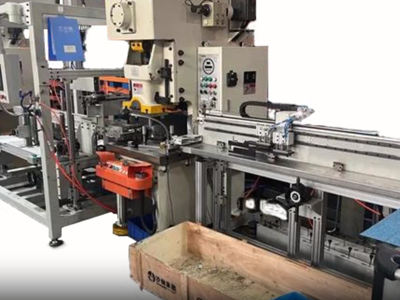

Hexahedron outside defect detection

The six faces of the hexahedron must be turned over once, so three faces are detected at a time, and then the other three faces are detected after the diagonal of the hexahedron is rotated by the manipulator, so that the six faces of the hexahedron workpiece can be detected without dead angle defects.

Device Video

Related Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.