Defect Detection in Workpiece Motion

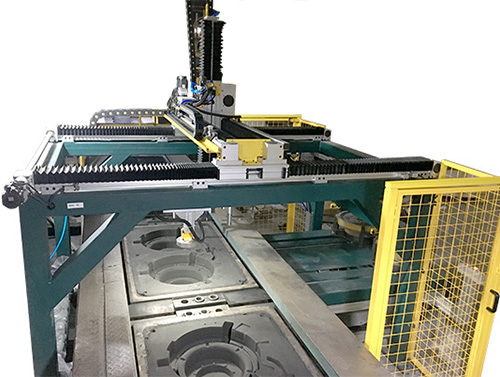

The moving position of the workpiece must correspond to the triggering time of the camera when the moving state of the workpiece is photographed.

Key words:

Classification:

Product Description

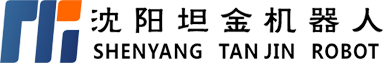

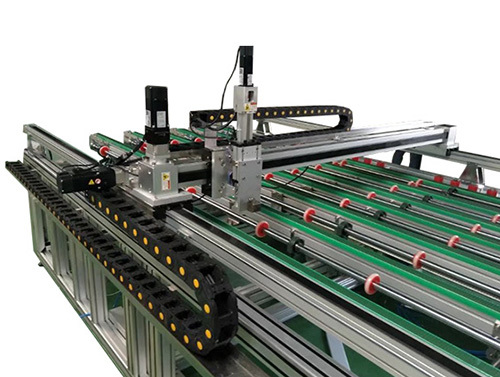

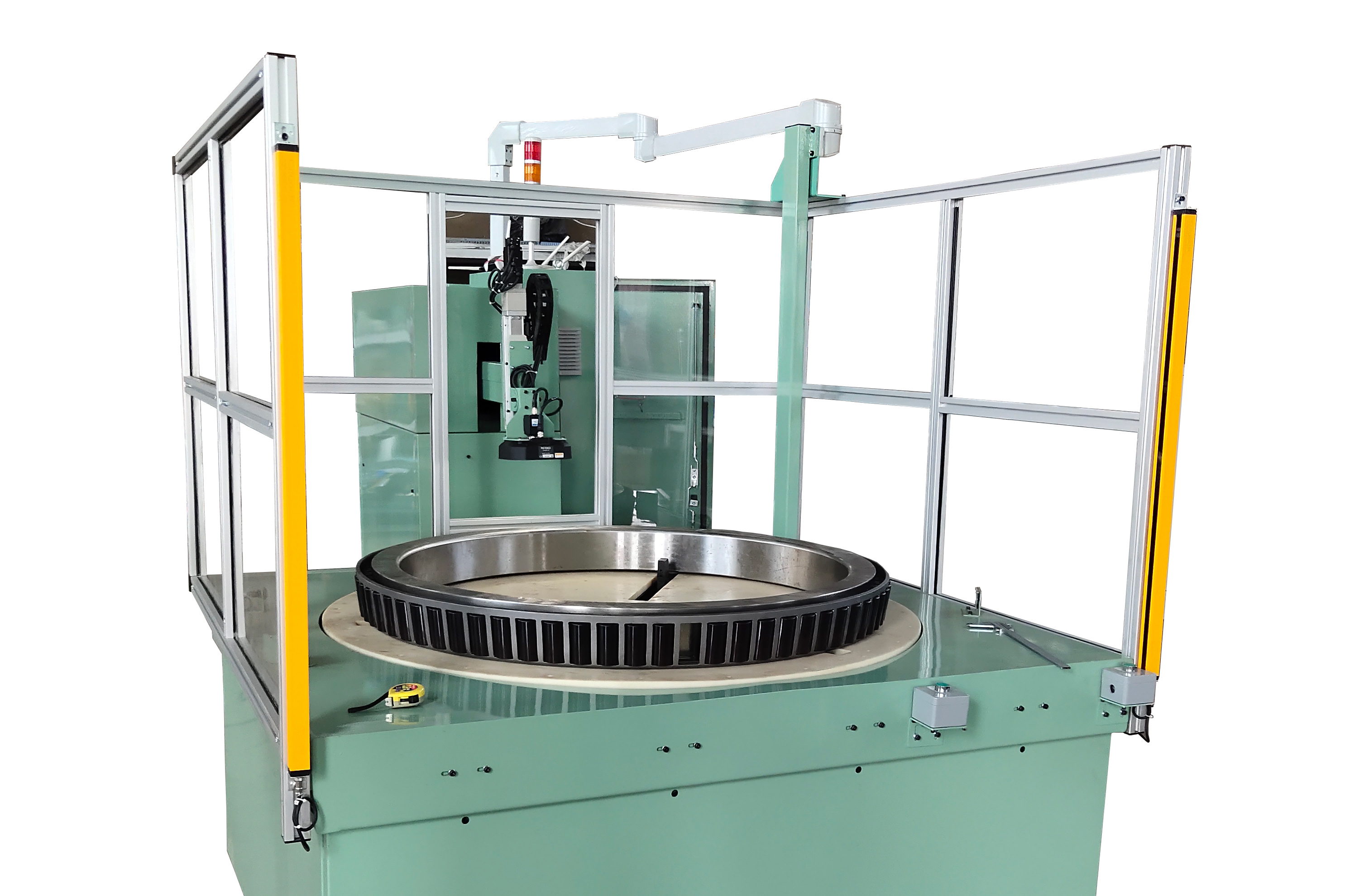

Bearing roller detection

1500 diameter bearing roller end face detection cannot be met by one camera pixel and field of view, and the roller generally has outer inclination, even if the camera field of view and pixel are met, the field of view cannot be met, only a single roller can be detected during rotation on the rotating platform, and the roller position must correspond to the camera trigger time during rotation of the bearing.

Detection of bearing beat: bearing (80-100 ball)/50 seconds

Detection bearing diameter: 1200-1500mm

Detection of bearing thickness: 30-100mm

Device Video

Related Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.